Applying Proven Cutting-Edge Technology to Cement: How our Autopilots CMO, VMO & KPO Perform

Modeling & Validation

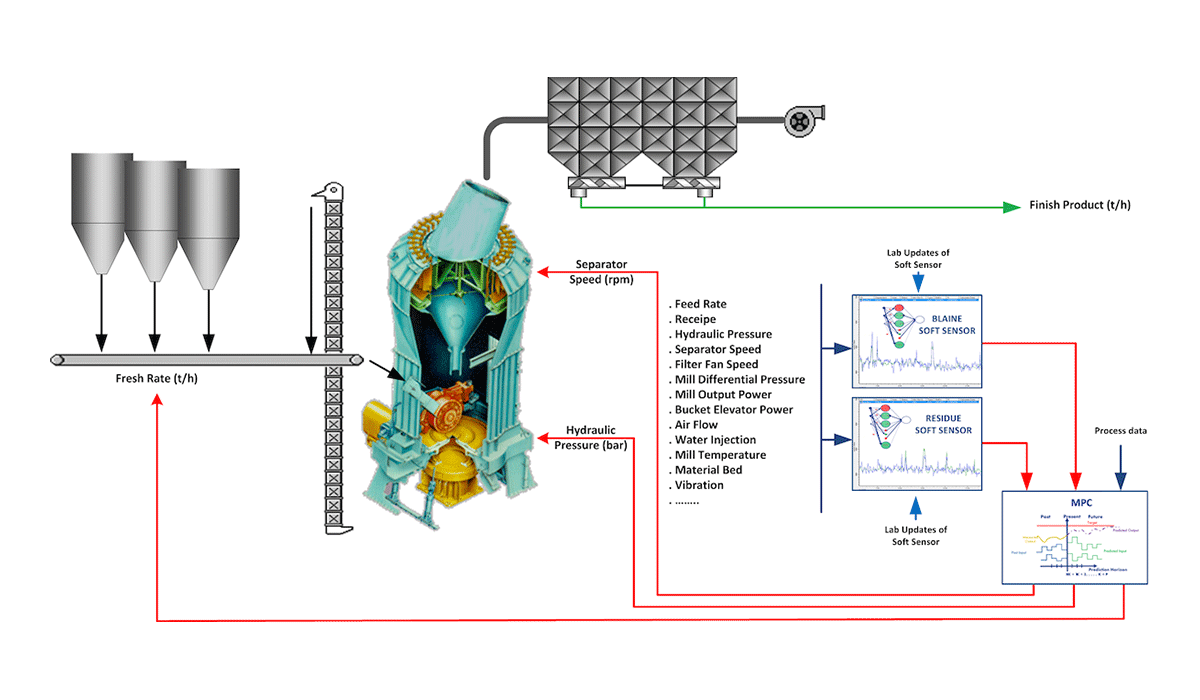

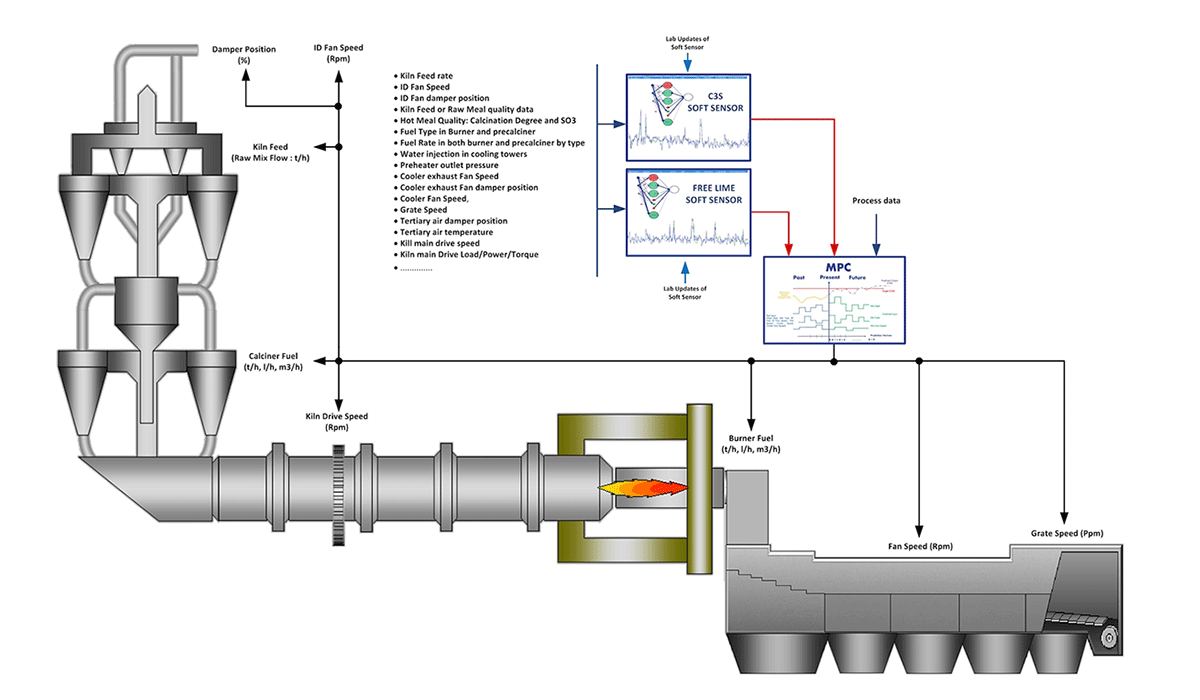

Data Input: Big data based on historical process data and onsite tests are combined with laboratory data to build ‘Soft Sensors’ that will accurately predict cement fineness, both blaine and residue, as well as clinker C3S and free lime, based on the full range of performance parameters.

Soft sensors: Our soft sensors are very sophisticated models formed by combining our multiple data-based algorithms adopted from machine learning and based on linear and non-linear identification techniques, PLS, and genetic algorithms. Capable of determining the best correlation between different process parameters and quality results, they’re able to very accurately predict the blaine and residue every 30 seconds.

MPC: Our MPC is a highly complex multivariable model based on transfer functions that we build by performing different impulse tests for each mill. Handling complex plant dynamics including long-dead times, non-minimum phase behavior, constraint handling, hierarchical and weighted optimization, and predictive control, it’s able to adjust every 30 seconds to process manipulated variables such as mill feed, separator speed and hydraulic pressure (for vertical mills) as well as kiln feed, main burner fuels, PC fuels, ID fans speed, waste air fans speed, kiln speed and cooler speed. Learn More

Prediction Validation: The customized model produced by our algorithms is then validated through extensive testing on both historical and live data.

CMO & VMO Operation

At each interval, the ‘Soft Sensors’ predict the blaine fineness and the residue value based on several inputs of mill measurements (weight feeders t/h, mill inlet/outlet pressure, bucket elevator Kw, Main Motor Power, Separator speed, Reject, etc.). The blaine and residue inferred values, are sent as a measurement inputs along with many online process parameters to the Model Based Optimizer or Model Predictive Controller to calculate new optimum setpoints for process manipulated variables such as separator speed, mill fresh feed and hydraulic pressure (for vertical mills).

Using this approach, mill operation is consistently pushed to the operational ideal targets due to the continuous prediction of blaine and residue combined with the optimal adjustments of operating conditions.

KPO Operation

The ’Soft Sensors’ predict clinker C3S and free lime based on the online process parameters of the kiln process including preheater and cooler (kiln feed, fuels, kiln speed, fans speed and power, temperatures, pressure, gas analysis, etc.). Together with many online process parameters, the predicted clinker C3S and free lime will be inputs to the Model Predictive Controller which will manipulate simultaneously kiln feed, kiln speed, fuels , fans speed, cooler operation and others.

KPO will boost the kiln performance by accurately predicting the clinker quality and continuously stabilizing the operation while optimizing the process targets.