While our Cement Mill Optimizer represents the state-of-the-art…

We offer a long track record of success in the design and engineering, integration and installation, and support and maintenance of conventional DCS & process control systems as well.

ADVANCED PROCESS CONTROL

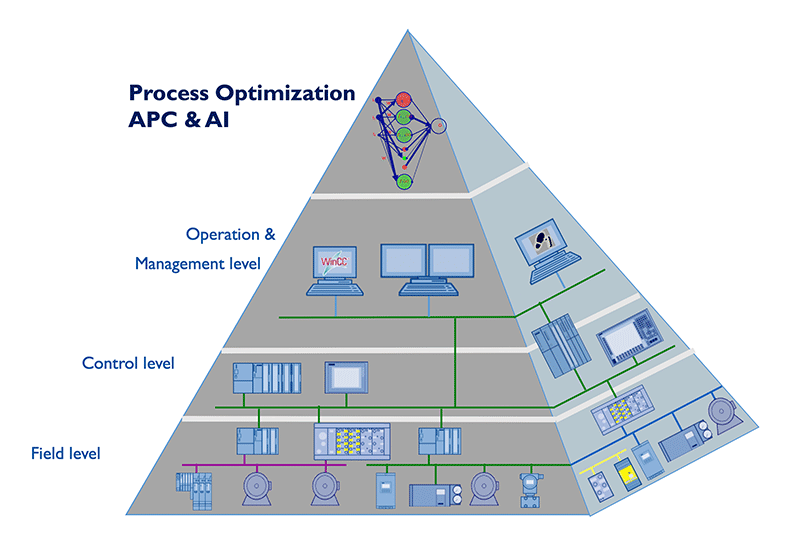

Ranging from Model Predictive Control (MPC) to the latest Artificial Neural Networks (ANN) and genetic algorithms, we design and implement Advanced Process Control (APC) solutions that model nonlinear complex systems in order to optimize cement manufacturing processes.

With APC – using different combinations of the most advanced algorithms and neural networks technology – even complex situations can be mathematically described through process parameters or variables to enable data-based, automated plant operation. By providing precise process management, it can significantly reduce the consumption of energy and raw materials for increased profitability and lower operating costs, while maintaining high quality standards and allowing for more flexible production.

PROCESS CONTROL & DCS SYSTEMS

Our ultimate DCS platform for the cement industry offers absolute transparency and significantly greater productivity in all areas of the cement industry. This includes everything from I/O level to centralizing the entire plant operations in the CCR, including energy management, data traceability and production and quality reporting.

As a Siemens Solution Partner Industry Specialist, we master the implementation of tailor-made CEMAT integrated process control systems, and play a key role throughout all corporate levels of the cement industry and in all phases of cement production.

MFG. EXECUTION SYSTEMS

Analyzing your (KPIs) based on your current process production values, energy consumption and manpower will give you the ability to benchmark and compare different sites, and predict your supply by comparing it to the current market demand. This is one typical example on how an intelligent MES system can lower your Total Cost of Ownership (TCO).

Our plant intelligence solution starts at the top plant management level, whether it is an MES or MIS system, to support accurate decision making by the plant management team. It is designed so that lower data streams from the factory floor level feed up to the top level to assure organized and easy data availability and transparency, traceability, follow-up and quality control.

MV & LV DRIVE TECHNOLOGY

One of a handful of Siemens Solution Partners offering retrofitting and other energy efficient drive system solutions, we can provide you with a very wide-ranging collection of energy efficient drive systems. From system design and supply component products themselves to support and maintenance, we help you maximize productivity and cost savings.

ELECTRICAL SOLUTIONS

ES Processing supplies full electrical packages specifically optimized for the cement industry such as power distribution, motors & drives, electrical rooms and cabling along with design layouts and technical specifications, supervision, installation and commissioning.

MIGRATION & MODERNIZATION

We’re expert at plant migration/modernization to help companies meet the challenges of increasing market competition, product standardization, environmental compliance, and cost reduction. At ES Processing, we’ve developed a proven and structured methodology, tailored to individual client needs, that minimizes the cost, downtime and risks of revamping old process control, electrical distribution, drive technology, and other components required for plant modernization. LEARN MORE >