Setting New Standards for Cement Process Performance

Our Cement Optimizers enable you to fully autopilot the cement processes to assure optimal manufacturing conditions.

We achieved this proprietary breakthrough by applying the latest Advanced Process Control (APC) and Artificial Intelligence (AI) to cement process.

How it Works: ‘Soft sensors’ provide near-continuous quality prediction of cement fitness (blaine and residue) and clinker quality (C3S and Free Lime) every 30 seconds versus the 1-2 hour lag time required for conventional manual lab testing, and then auto adjust the process Manipulated Variables every 30 seconds based on tailor-made mathematical transfer functions, sophisticated algorithms & MPC rather than subjective operator expertise.

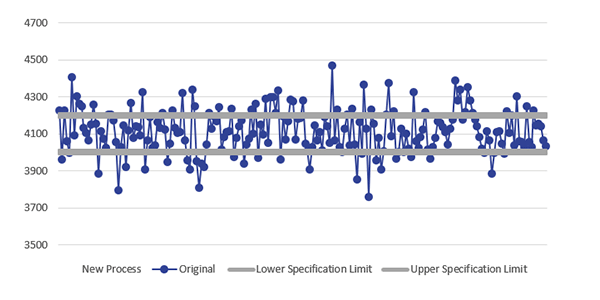

FINENESS: BEFORE APC-AI

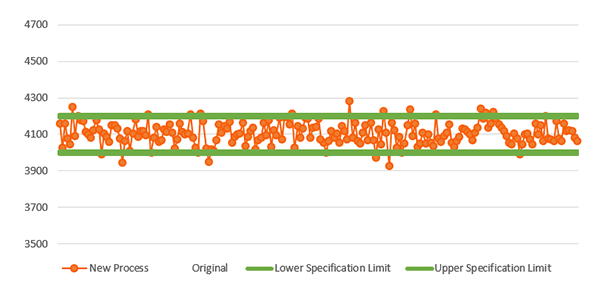

FINENESS: WITH APC-AI

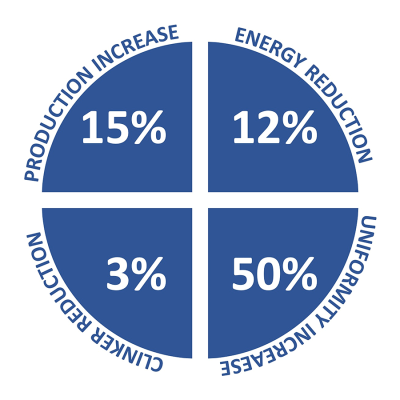

Our Optimizers’ Benefits:

-

Fully Autopiloting cement mills and kilns

-

Increasing cement production up to 20%

-

Reducing CO2 emissions and lowering environmental impact

-

Improving plant OEE (Overall Equipment Efficiency) by enhancing quality, performance and availability

-

Enhancing clinker quality = lower clinker factor

-

Enhancing cement quality = higher cement strength

-

Enhancing clinker and cement uniformity

-

Reducing Specific Energy Consumption = lower energy cost

-

Reducing stress loads and equipment wear = lower maintenance cost

-

Reducing Opex by lower clinker factor, lower energy cost & lower maintenance cost

-

Improving operators’ competencies to assist in plant optimization

-

Fast PAYBACK

See how it’s implemented >

Get full support for legacy control systems

In addition to CMO, we provide design and engineering, integration and installation, and support and maintenance of conventional DCS & process control systems too!

The Challenges We Help Cement Industries Solve

New Market Pressures and the Innovation Gap

Cement manufacturers face rising competition, ever-increasing raw material and energy prices, and the need to comply with stricter environmental protection policies. Innovation is needed. But the uniquely hostile environment inside cement manufacturing plants make innovating processes a challenge.

The ES Processing Optimizers (KPO/CMO/VMO) are specifically designed to enable cement manufacturers to immediately innovate their process to maximize output, quality and efficiency.

Inability to Leverage Advanced Process Control

While manufacturers in other sectors have been able to upgrade processes with advanced process control, cement manufacturers have been unable to take advantage of it. Continuously measuring the quality of cement manufacturing in real time has been an impossibility since any measuring instruments that might be installed inside a mill or a kiln would be destroyed.

Our proprietary technology makes intelligent use of big data and transforms it into algorithms and models that serve as an ‘autopilot’ to achieve an unprecedented level of process optimization.

Reliance on Inefficient Manual Processes

Cement manufacturers have had to manually sample finished product and then test fineness and residue in the lab. Given the 1-2 hour delay this manual process entails, results often aren’t available until after production conditions have already shifted or finished product is already in storage silos – too late to correct product quality issues. Adjustments have also been a manual process. Based on test results, the operator must select new combinations of mill fresh feed, separator speed and hydraulic pressure (for vertical mills) hoping to achieve target fineness, based on their own experience and personal judgement rather than hard data. For kiln operators, the analysis is much more complicated with a vast number of possible decisions and combinations of actions.

By implementing CMO, VMO or KPO autopilot based on hard data rather than operator expertise, our APC-AI solutions empower you to achieve a much higher consistency of product quality and production efficiency.

High Standard Deviation from Target Quality

The inherent imprecision of a manually controlled process usually results in high standard deviation from the quality target and in non-uniform product. Quality suffers. Plus, less frequent larger adjustments that rely on subjective human judgement results in higher-than-necessary electricity usage and greater wear and tear on machinery.

ES Processing enables cement mills and kilns to leverage data-based APCs to assure consistent product quality.